ISOF researchers are actively committed to discover new molecules and materials, develop new technological applications, disseminate their results in scientific publications and international conferences, organize events for the broader public, publish books.

-

Research fellowship on Materials Chemistry and Analytical Chemistry

Call for application n° ISOF_291_2024_BO Application Deadline: May 2nd, 2024 We are currently seeking a freshly graduate Research Fellow to join our research group, under the …

-

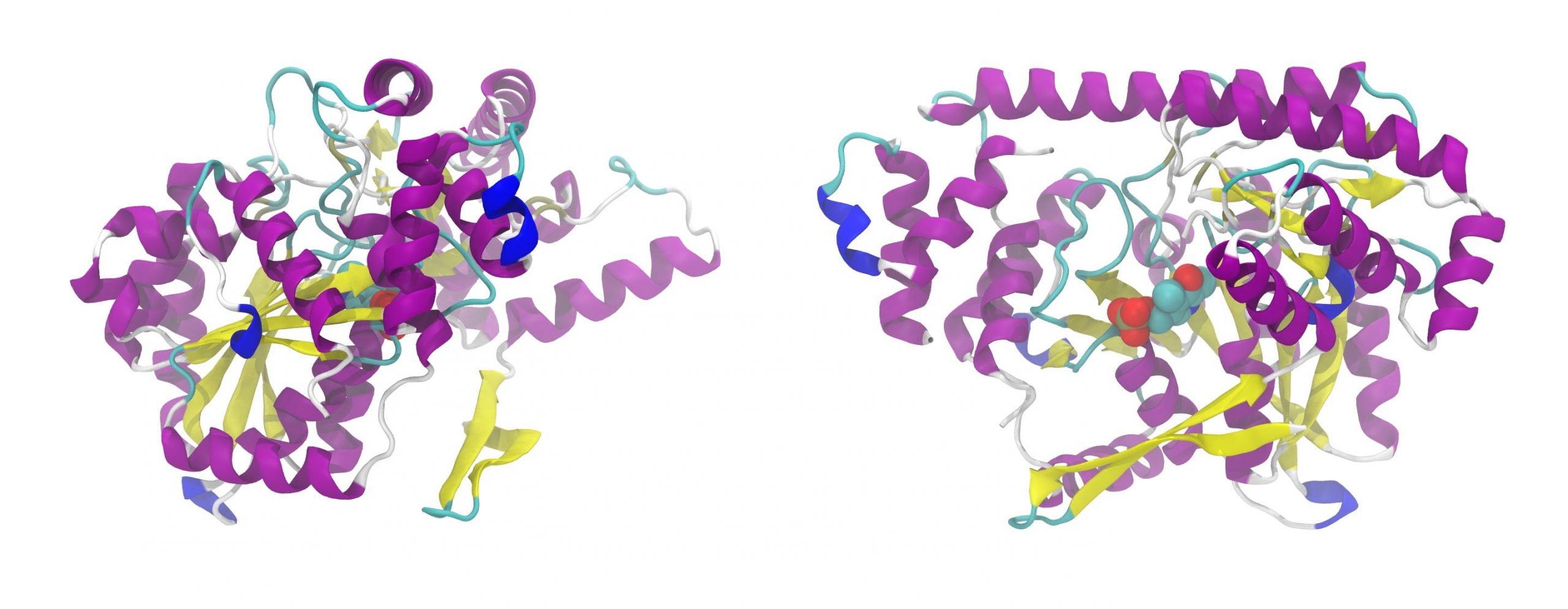

How to make structural batteries more eco-friendly

A new study shows the use of ethanol as a solvent for coating carbon fiber electrodes with graphene

-

ISOF at the Mineral Show 2024

ISOF participated at the Mineral Show 2024 with great success.

-

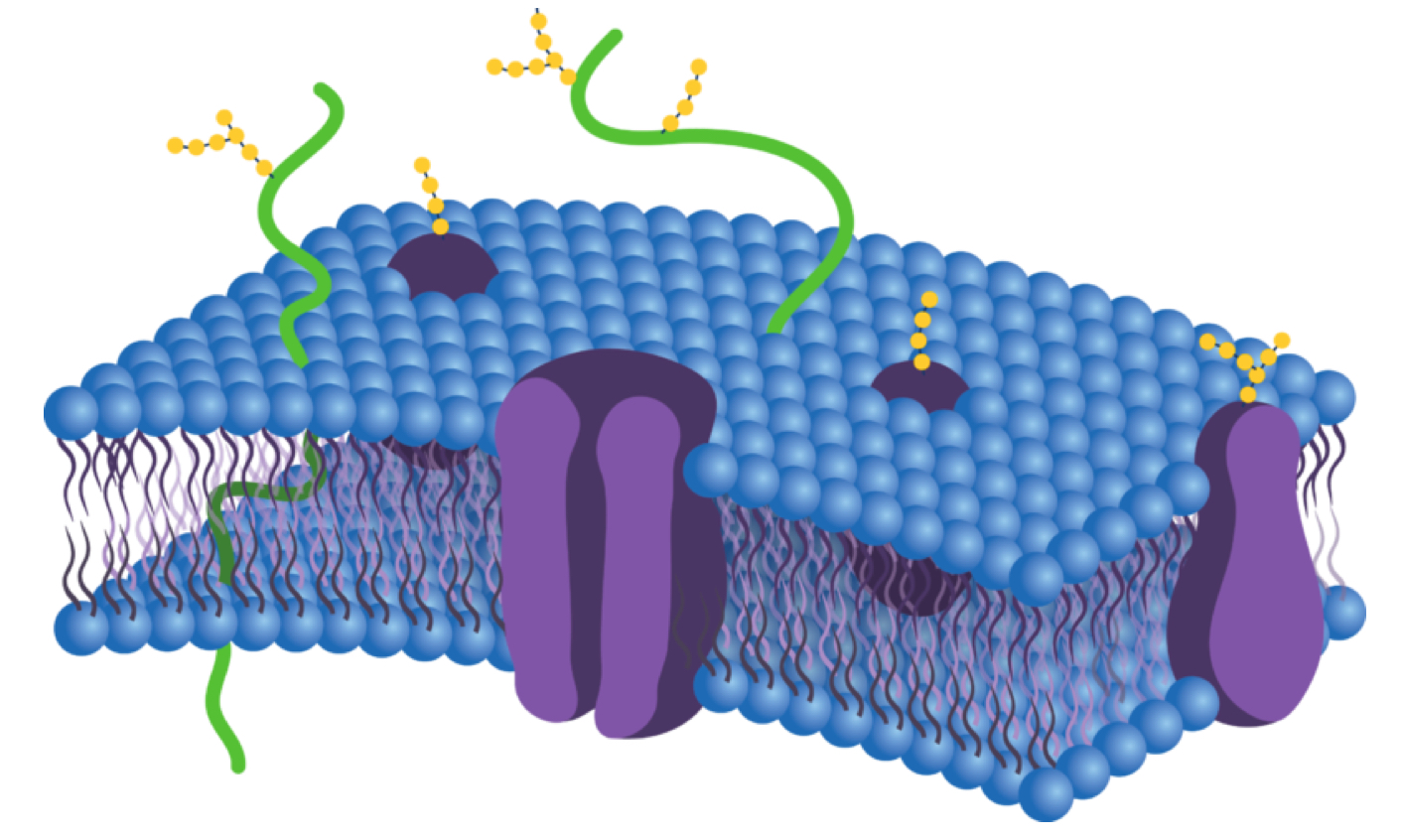

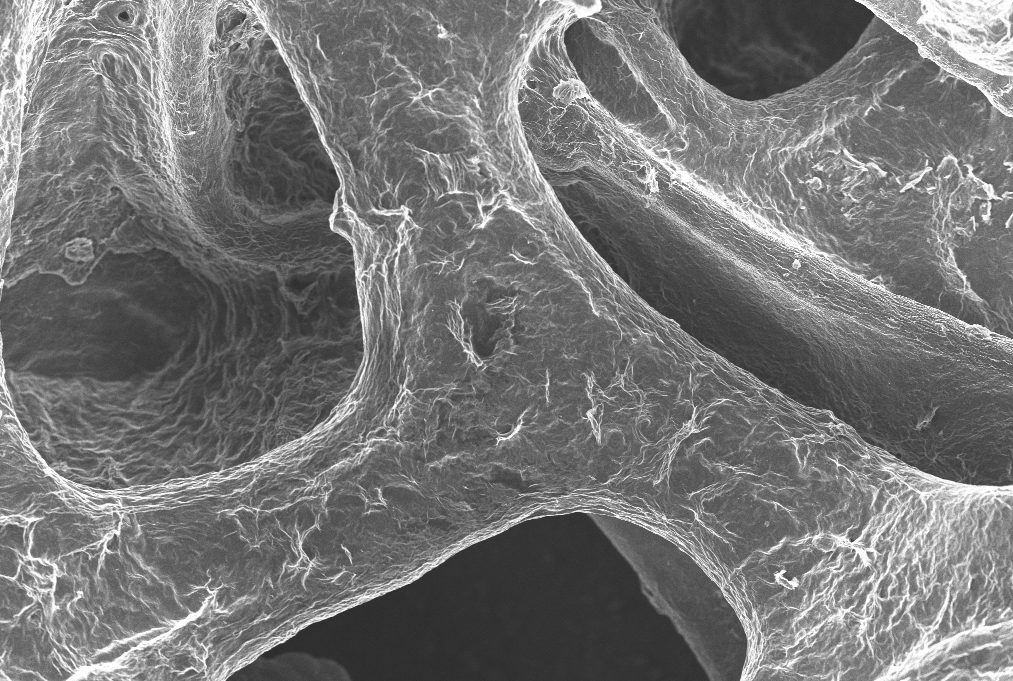

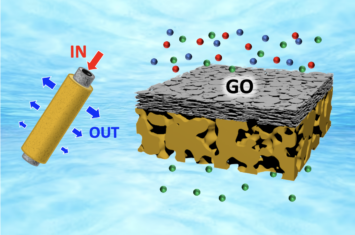

Selective ion filtration demonstrated on commercial filters

Graphene oxide can be applied on everyday devices to selectively filter ions.

-

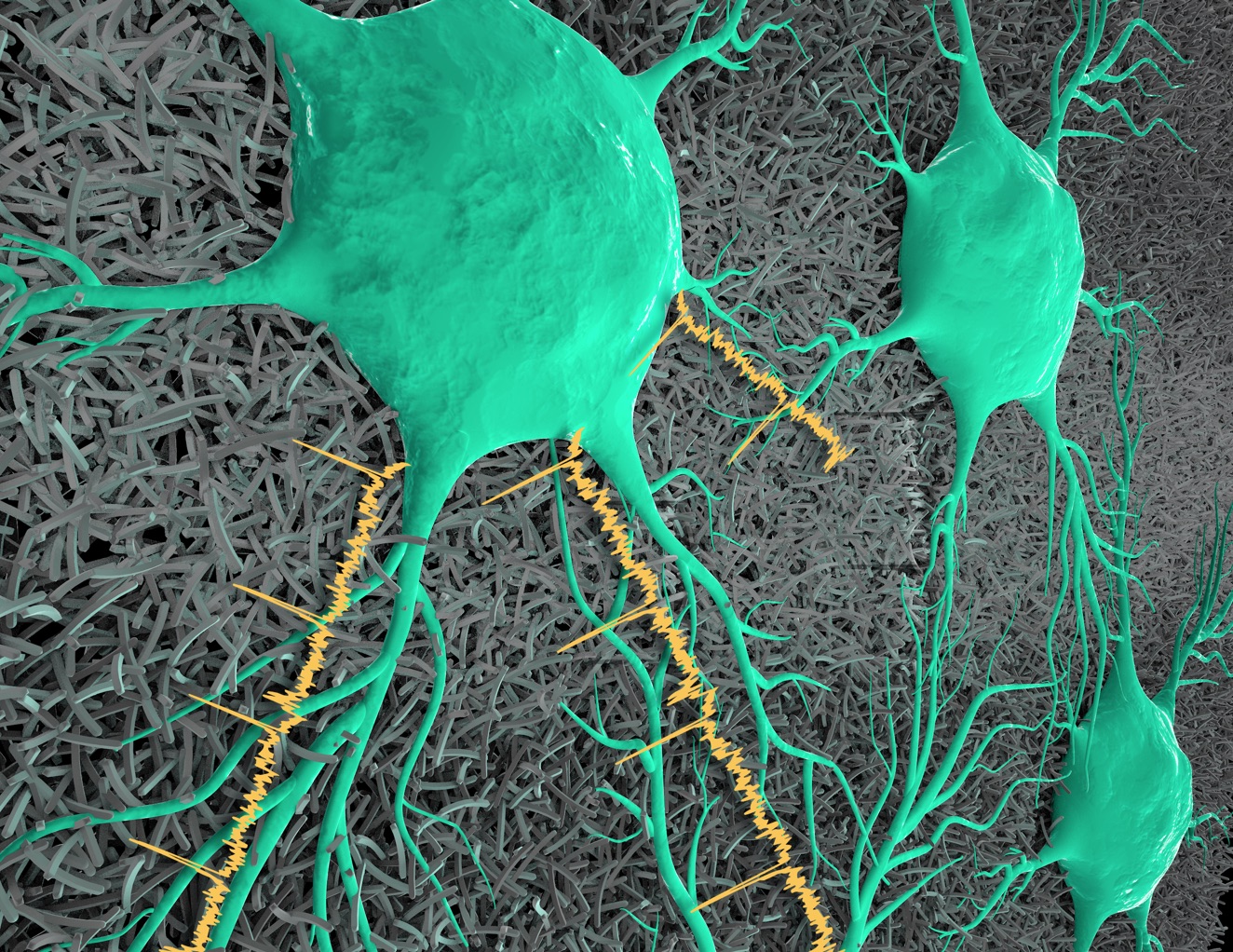

Valentina Benfenati at the RIKEN Europe Symposium 2024

The RIKEN Europe Symposium 2024 “Science and technologies, platforms and collaboration for researching human physiology and diseases: enabling organoids” was held on 14th February 2024 …

-

A new “Water living lab” inaugurated in Ferrara

The lab will test nano-materials for removal of pesticides, PFAS and other contaminants from our water.

-

Job openings for researchers in organic chemistry, materials science and biology

We are looking for researchers to join research teams for PRIN projects, Projects of National Relevance. https://www.mur.gov.it/it/aree-tematiche/ricerca/programmi-di-finanziamento/progetti-di-rilevante-interesse-nazionale-prin Each project relates to specific research areas. Check …

-

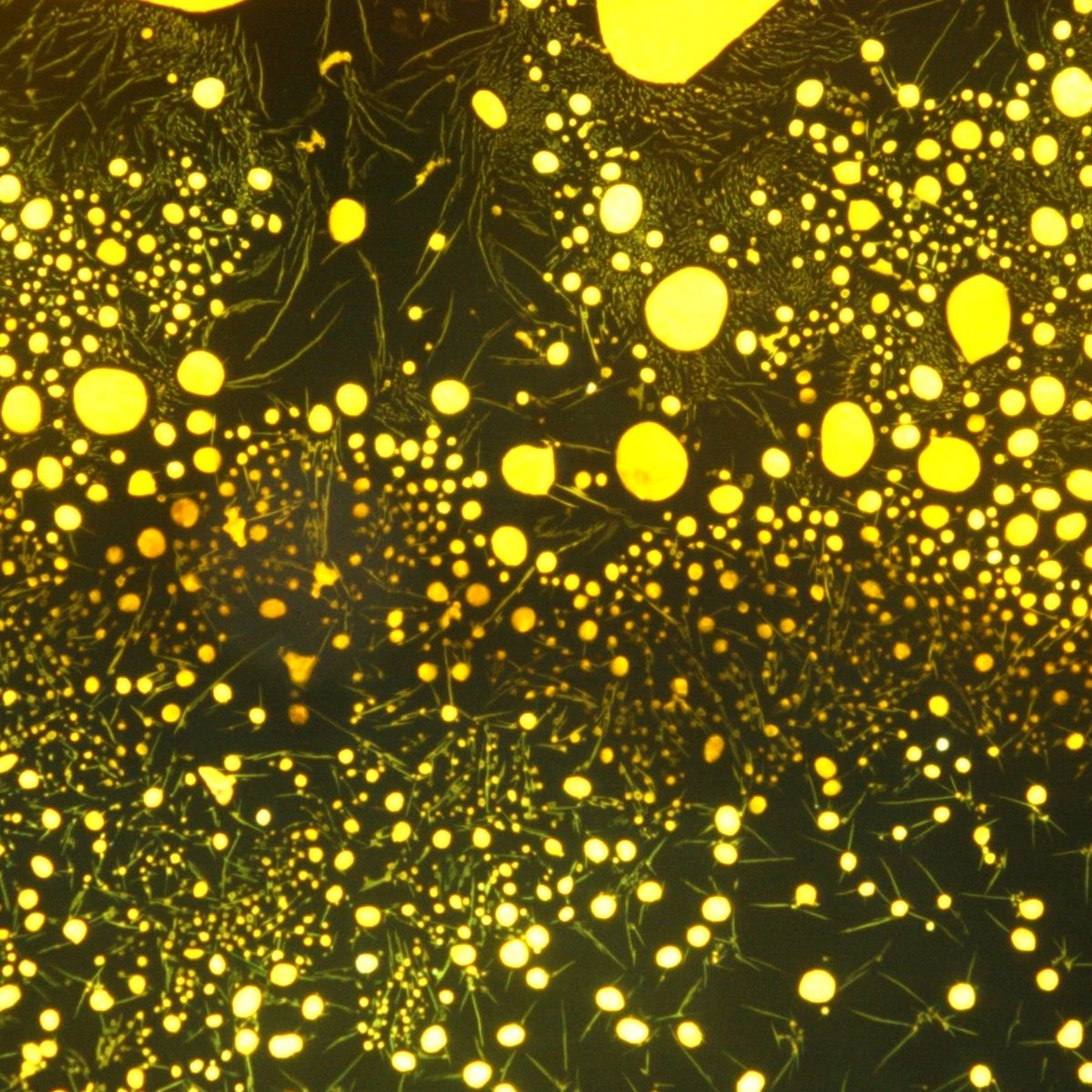

A new sensor to monitor glyphosate pesticides in tap water

CNR and University of Venice use Amino acid modified graphene oxide to capture and detect the pesticide.

-

Research position in acquisition and analysis of data produced by sensors, Artificial Intelligence and Deep Learning tools

ISOF_293_2024_BO Application deadline: May 20th, 2024 We are looking for a highly motivated researcher to join our efforts and carry out research activities related to …

-

Call for application ISOF-CNR 287: EU-funded MSCA Doctoral Network Grants

Marie Sklodowska Curie Actions Doctoral Network PhD Training Position (10 positions) Applications are invited from suitably qualified candidates for a full-time MSCA DN Doctoral Candidate …

-

CNR materials tested in space

New materials for radiation shielding will be tested in the international Space Station

-

Galileo e le fake news

Will social media destroy the authority of Science?